As logistics businesses are required to fulfill more deliveries within a shorter timeframe and at lower cost, it becomes obvious that they need a complete change of supply chain management. Luckily, artificial intelligence can offer such a transformation.

According to Meticulous Research, the demand for AI technology in logistics and supply chain management will grow, with a projected market size of $58.55 billion by 2031 and a CAGR of 40.4% from 2024. The statistics prove that AI in logistics will soon be an irreplaceable tool. It’s even more fair to say that implementing AI is already a primary goal for many companies to achieve. With this statement in mind, let’s explore what capabilities and benefits AI brings to logistics and transportation and what can be significant roadblocks for adopting this new technology in the industry.

Understanding the Role of Artificial Intelligence in Logistics

Artificial intelligence feeds on the impact of big data, the collected information from logistics processes, and automates tasks, ultimately unlocking new functionality for streamlining processes and reducing expenses. The McKinsey report shows that businesses, which quickly adopted AI-driven supply chain management, experienced operational enhancements. Those are a 15% cost reduction, a 35% decrease in inventory levels, and a 65% increase in service levels.

McKinsey further highlights the improvements possible with AI in logistics. For example, thanks to forecasting with AI, it is possible to reduce supply chain’s errors to 20-50%. At the same time, warehouse and administration costs can be decreased by 5% to 10% and 25% to 40%, respectively.

So, you may ask: “How is artificial intelligence used in the logistics industry so that it saves costs and reduces error?” To answer this question, it is necessary to mention the following logistics AI use cases:

- Optimization of route planning, minimizing expediting deliveries;

- Improvement of inventory management, reducing wasted resources;

- Automation of manual efforts, allowing employees to focus on strategic activities;

- Streamlining of delivery, boosting customer experience.

AI capabilities used in logistics also impacts other industries with one of the prominent examples being manufacturing. As long as supply chain management driven by AI can supply manufacturers with real-time insights, factories can optimize inventory management, reduce storage costs, and ensure there are no potential material shortages.

Willing to learn about the impact of AI and ML in manufacturing?

Read our detailed article!

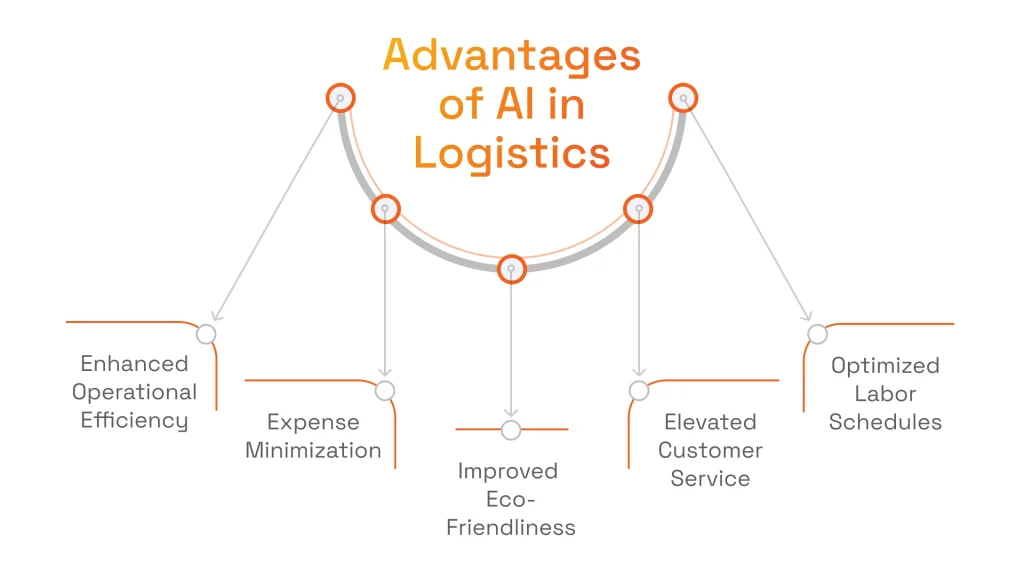

Advantages of Integrating AI in Logistics

In logistics, AI completely transforms how companies operate. By integrating artificial intelligence into their operations, logistics service providers are unlocking multiple benefits that change how the way goods move around the world. Below is a closer look at some of the key benefits of AI in logistics.

Enhanced Operational Efficiency

According to Statista, a 2022 survey revealed that 60% of companies worldwide expect robotic process automation (RPA) to transform supply chains by 2025. Logistics companies can benefit from this technology that allows them to imitate human actions and automates repetitive, rule-based tasks. AI-powered robots can free up human employees by handling such processes as:

- Inventory management since robots equipped with sensors and AI can monitor inventory levels, identify low stock, and generate automatic purchase orders;

- Warehouse management as robots pick and pack orders, transport goods, and optimize storage layouts based on product characteristics and access frequency;

- Quality control as vision systems can perform automated quality checks the accuracy of completing different processes;

- Predictive maintenance since robots’ sensors can continuously monitor equipment health.

Serhii Leleko

AI&ML Engineer at SPD Technology

“Besides RPA, AI algorithms can be also used for intelligent automation. AI performs data entry, order fulfillment, and shipment document processing faster and more accurately compared to humans.”

Expense Minimization

As said above, artificial intelligence can enable intelligent automation services to accelerate and optimize routine processes. That means logistics companies can streamline their operations and, as a result, achieve significant cost savings. The McKinsey Global Survey confirms this, as it is revealed that 44% of executives whose companies have adopted AI claimed that this technology has reduced costs.

To guarantee costs reduction, AI in logistics and transportation helps companies to achieve:

- Minimized fuel consumption by optimizing delivery routes based on historical traffic patterns, weather conditions, and real-time road congestion analysis;

- Timely equipment maintenance by predicting potential supply chain problems based on vehicles sensor data analysis;

- Supplying according to demand by gaining insights into historical sales data, customer behavior patterns, and market trends;

- Reduced issues by automating repetitive tasks prone to human errors.

Improved Eco-Friendliness

Transportation of products entails huge fuel consumption. However, Accenture states that AI-driven data analysis can be used to minimize greenhouse gasses emission and air pollution. To be more precise, harnessing data from supply chains, weather patterns, and even consumer habits allows companies to optimize routes and supply processes to reduce the usage of fuel within the transportation and logistics industry.

The companies can optimize fuel consumption and consequently improve their eco-friendliness by using AI in logistics for:

- Forecasting demand to have enough stock to meet customer needs and avoid unnecessary resupply.

- Predicting disruptions due to weather conditions since AI can suggest alternative routes or adjust delivery schedules to minimize delays caused by disruptions.

- Eliminating unnecessary shipments as accurate demand forecasts minimize the need for last-minute expedited deliveries.

Elevated Customer Service

One of the most powerful functionalities offered to customer service by AI is personalization. Particularly, NLP and machine learning improve communication between businesses and customers by understanding contextual data, defining customer sentiment, and generating natural conversations. Equipped with these technologies, businesses can create chatbots that respond to customer queries 24/7 with appropriate information.

Additionally, artificial intelligence transforms customer service for logistics companies with:

- Real-time tracking with accurate estimated time of arrival (ETA) to keep customers informed;

- Automated notifications about potential delays or disruptions;

- Predictive issue resolution based on data about customers, shipments, delays, etc.

We know for a fact that the automation and real-time capabilities in logistics applications (that are often achieved thanks to AI) can make customers happy. For instance, our team executed mobile and web app development for logistics company and delivered such features as real-time cargo tracking, route selection, and document scanning, which made deliveries much faster and clients, consequently, more satisfied, loyal, and confident in the service.

Optimized Labor Schedules

AI doesn’t replace human workers in logistics. Instead, it empowers them. McKinsey reports that AI has enhanced the productivity of field workers by 20% to 30% and schedulers by 10% to 20%. Smart scheduling promotes effective and fair labor planning. With AI systems, logistics businesses receive a consistent approach to addressing productivity of personnel.

Artificial intelligence in logistics improve productivity thanks to:

- Elimination of human bias, when AI creates objective schedules that distribute workloads according to responsibilities;

- Automated analysis of such factors as employee skills, workload demands, and even traffic patterns for delivery drivers.

- Proactive response to disruptions as AI analyzes real-time data on traffic delays, weather events, or even equipment issues for allocating additional human resources.

Applications of AI in the Logistics Industry

Artificial intelligence brings significant advancements across a wide range of logistics operations. Many companies have already adopted AI to cover specific needs. Let’s delve into the most standout examples of how AI is used in logistics.

Route Optimization

DHL, a global logistics service provider, uses AI-powered route planning software to improve its shipping process. The company’s system analyzes all delivery points on a route, prioritizing them based on urgency like critical medical deliveries or those needed before 9 am. It also factors in distance between stops to create the most efficient route sequence. DHL highlights that AI enables faster deliveries with less fuel consumption, while their customers benefit from more accurate delivery time windows.

Indeed, traffic analysis and optimization with AI in transportation and logistics can lead to customer satisfaction. We know that for sure, as we leveraged AI for a transportation construction company. By integrating AI into the system, we made it analyze traffic patterns across construction areas, providing insights into how construction work impacts road traffic before, during, and after construction. Our efforts resulted in efficient route optimization for more than 500 contractors in the US.

Proactive Maintenance Predictions

One of the notable AI in logistics examples is presented by Paccar, the American company that designs and manufactures large trucks used in the transportation industry. The company leverages machine learning for predictive maintenance, forecasting truck repairs before they create disruptions on the road.

The company equips trucks with a combination of hardware and software that unlocks the power of their data for quality control. Such use of AI in logistics translates into proactive maintenance, allowing them to predict and address potential issues. Now, companies can make informed operational decisions, ensuring their trucks stay on the road and their deliveries arrive on time.

Demand Forecasting

Amazon employs deep learning, image recognition and natural language processing (NLP) capabilities to achieve accurate demand forecasting with machine learning. Predictions of demands are achieved by analyzing large volumes of historical sales data to identify complex patterns, extracting insights from product images, and analyzing customer reviews and search queries to understand evolving customer preferences.

Furthermore, Amazon is exploring the application of deep reinforcement learning (DRL) to optimize logistics and supply chain operations based on the enhanced demand forecasts. The company states that DRL offers the potential to translate forecasting precision into cost savings.

Automated Warehousing Processes

Honeywell, a company that develops safety and productivity solutions, came up with the AI-powered robotic system for order picking and sorting. The solution helps logistics service providers to increase efficiency and accuracy in warehouse processes as well as reduce human error. This is achieved by maximizing floor space and managing over 20,000 SKUs using shuttles.

The company emphasizes that this use of AI in logistics delivers a 40% increase in throughput, enabling warehouses to optimize labor allocation. This integration of logistics and AI contributes to minimization of manual processes and significantly lower operational costs.

Supply Chain Management

Unilever uses AI to ensure a smarter and sustainable supply chain. The company’s data scientists and ML engineers fine-tune AI algorithms to check real-time data from suppliers, manufacturers, and retailers. Hence, this global FMCG company gains a holistic understanding of their supply network.

One of the major benefits of AI in logistics is supplying alternative ingredients for products, mitigating potential disruptions, or stabilizing prices. This strengthens the overall resilience of the company’s supply chain. Additionally, integrating AI into Unilever’s system enables the development of more sustainable product formulations. By identifying unnecessary ingredients, this personal care and food production company reduced environmental footprint and streamlined manufacturing processes.

Want to know how artificial intelligence revolutionized the food industry?

Find out in our article!

Fraudulent Activity Detection

One of the most prominent examples of fraud prevention in logistics is UPS and their DeliveryDefense system. The global delivery company uses machine learning algorithms that analyze historical data and assign each location a delivery confidence score. This score takes into account various factors, such as past delivery attempts, time of day, location characteristics, and even weather patterns.

Such a fraud detection system is equipped with anomaly detection powered by machine learning. This means the system continuously monitors incoming data for deviations from the established patterns.

Customer Support and Chatbot Implementation

A retail company Lowe’s developed a chatbot that can answer customer questions and assess their preferences. In such a way, chatbot generates personalized product recommendations. This smart combination of AI and logistics processes not only enhances the customer experience but also increases the potential for relevant upselling and cross-selling opportunities.

From our experience with HaulHub, we know how to ensure fluency in the chatbot’s generated responses. We integrated a Retrieval-Augmented Generation (RAG) approach for chatbot conversations for providing contextual information. This approach allows us to achieve a seamless retrieval of the information from the company’s data that is later used to elaborate clear answers to inquiries.

Real-Time Vehicle Monitoring

One of the most popular logistics service providers FedEx combines AI/ML with sensors for capturing autonomous cargo shipping data and leverage predictive analytics for harnessing data-driven insights. Their AI system tracks shipments by fetching data every two seconds to provide real-time information.

By processing a vast amount of data with machine learning, FedEx enables a more transparent and predictable supply chain, bringing advantages to the company and its customers.

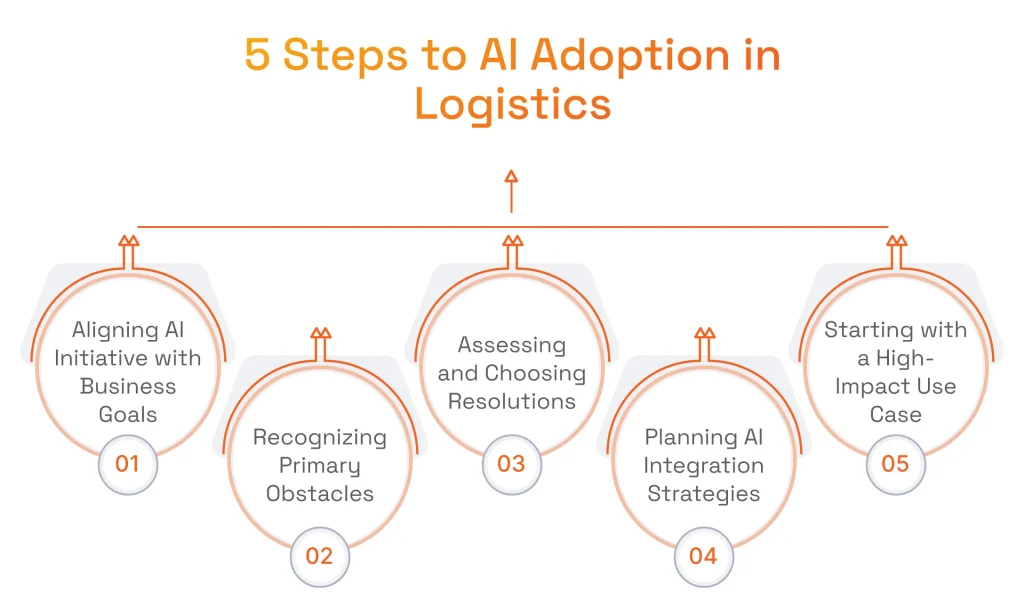

How Logistics Companies Can Start Embracing AI Innovation Step-by-Step

Integrating logistics and AI never sounded like a one-step achievement due to the complex nature of both the industry and advanced technology. So, there are some foundational steps that logistics companies should take to get their enterprises ready for gradual AI transformation.

Aligning AI Initiative with Business Goals

First thing every logistics company must do is to understand how AI will address overarching business objectives like increased operational efficiency or improved customer satisfaction. It is advisable to hold meetings with stakeholders to agree on which needs AI is meant to cover. During these meetings, stakeholders should determine the company’s most pressing challenges or growth areas. For example, those can be reducing delivery times, minimizing carbon emissions, or optimizing warehouse management with artificial intelligence in logistics.

Once these priorities are identified, the next step is to translate them into specific, measurable goals that align with the company’s strategic objectives. This involves defining KPIs to track the success of the AI initiative. For instance, KPIs could include metrics such as a percentage reduction in delivery times, a measurable decrease in carbon emissions, or an improvement in inventory accuracy.

Recognizing Primary Obstacles

The next step is recognizing potential roadblocks that can come up when leveraging AI for logistics. Financial constraints can be one of them. To address it, explore cost-effective solutions or start with a partial digital transformation instead of changing all the processes to AI-driven at once.

Skill gaps and unwillingness to change are also common challenges. To cover skill gaps, invest in AI training for existing staff or hire external experts for AI development tasks. In case your staff is not willing to embrace the change towards AI, clear communication and workshops for outlining of benefits can be helpful. During these workshops, you need to cover how AI can optimize manual processes and reduce workload to make the transition to AI-powered operations easier.

Another obstacle that many established companies face is a legacy system. Businesses that exist for decades find it hard to re-invent their system and approach data for AI implementation. It is essential to start with either upgrading IT systems to ensure compatibility with AI or exploring cloud-based AI solutions that minimize infrastructure dependence. Plus, companies should consider data strategy consulting for creating a robust data foundation. Consulting insights can help establish the most effective way to capture, store, and manage data so that it is ready for AI-driven insights.

Assessing and Choosing Resolutions

Once you know what problem to address, try and investigate your logistics operations to identify areas where AI can bring tangible results. For example, some of the most common starting points for logistics AI transformation are inventory management, warehouse optimization, or implementing predictive capabilities.

When you know what part of operations you are willing to change, research and compare different AI solutions, considering factors like functionality, features, cost, and scalability. After, develop a proof-of-concept (POC) as your pilot AI project. This will help you assess the solution’s effectiveness and suitability as well as correspondence to your specific needs.

Planning AI Integration Strategies

A successful AI implementation must have a clear action plan that must address necessary technologies as well as have a coherent data strategy framework.

When choosing AI platforms to integrate, the attention should be paid to how these technologies serve your business needs. Answer the following questions:

- Do you need to standardize and cleanse data with an enterprise data warehouse?

- Do you need a cloud-based solution or custom-build models?

- Do they operate seamlessly with your current applications?

- Will these platforms support higher volumes of data and more complex algorithms over time?

Once you know the answers, your integrations of AI in logistics industry have a higher chance of interoperability, scalability without compromising the existing processes.

When it comes to data strategy framework, it is essential to meticulously address data quality management, data governance, and data security measures. The first need to include measures for cleaning, validating, and standardizing data to remove errors, inconsistencies, or redundancies. The second ensures that data is used responsibly and complies with legal and regulatory standards. The third sheds light on how to implement security protocols, such as encryption, multi-factor authentication, and regular vulnerability assessments.

Willing to know more about how data strategy helps large businesses to take the path of innovation?

Find out in our article about enterprise data strategy.

Starting with a Focused, High-Impact Use Case

The evaluation of needs and resolutions chosen often uncover several desirable areas of AI applications. In that case, stakeholders must prioritize high-impact areas during workshops. The best strategy here is to put high ROI projects first and select initiatives that provide measurable and rapid returns to build the company’s confidence in the role of artificial intelligence in logistics.

High ROI projects must address the following criteria: addressing pressing pain points (for example, automation of manual tasks), cost savings (because of reduced labor costs, lower material waste, or energy savings), feasibility (resource availability, flexibility, scalability), low risks (minimum data quality issues, no disruption of existing workflows, etc.). Sure thing, these criteria vary but the examples are the most common aspects most businesses consider.

Serhii Leleko

AI&ML Engineer at SPD Technology

“A successful AI transformation in logistics isn’t about doing everything at once. It’s about starting small, focusing on impact, and building confidence step by step. Align your goals, address the challenges, and let data and strategy guide the way.”

The Best Practices for Implementing AI in Logistics

Following best practices ensures that the implementation process is structured and less prone to costly mistakes. Your most attention in combining AI and logistics processes must be focused on data quality, automation, employee training and phased implementation.

Ensuring Data Quality and Accessibility

Clean and high-quality data in the foundation of AI implementation. It is crucial to ensure that the data used for AI is free of errors or duplications, unified from all the possible sources, and accessible to relevant AI models.

To ensure data corresponds to the mentioned properties, our team employs advanced ETL pipelines to clean and integrate data efficiently. For example, in a recent project for HaulHub, a transportation construction company, we aggregated data from four separate systems into a Data Lake to ensure consistent AI-powered analytical insights.

To ensure real-time access to data, we design systems that support real-time data ingestion. In this way, AI solutions can provide timely recommendations, such as dynamic route optimization or predictive inventory alerts.

Automating Repetitive Processes and Enabling Intelligent Alerts

AI logistics automation, including data entry, shipment scheduling, and customer service inquiries, is one of the main arguments in favor of using advanced technology in the industry. With AI, it becomes possible to reduce errors and free up employee time for more strategic and creative tasks. At the same time, AI systems can send alerts for logistics providers to expect delivery delays, be aware of stock shortages, or identify maintenance needs.

To implement automation and alerts, we apply our RPA development services to streamline rule-based tasks (for example, data entry and invoice processing), and set up NLP to handle customer inquiries and automate communication processes (tracking updates or FAQs via chatbots). When it comes to alerts, our team prefers using ML models to analyze real-time and historical data. Models are set up to analyze and process data and trigger alerts when a certain pre-defined information comes up. After, we connect these alerts with notification systems through APIs to deliver actionable messages via email, SMS, or push notifications.

Investing in Employee Training and Change Management

AI implementation draws a lot of changes inside an organization, including those connected to the company’s culture and knowledge. Upskilling employees is important to manage this change as it ensures they can work effectively with AI tools and interpret their insights. On top of that, it is important to communicate the transition to AI and help employees to understand the benefits of AI to overcome resistance to new technologies.

We usually prioritize tailored training sessions for employees to help them understand the role of artificial intelligence in logistics. Plus, we work hand-in-hand with stakeholders and design phased rollout plans to support their adoption of AI-powered operations. This includes creating user-friendly dashboards and offering post-implementation support to address any operational concerns.

Implementing Gradually with Vendor Support

As data is clear and accurate, processes are set up and automated, and employees know how to interact with an AI-driven system, it is time to move to the next level. Based on preliminary work with the system, it is crucial to understand what areas need improvements or what enhancements will contribute to reach KPIs.

To see what functionality to add to the system next, we help our clients to continuously track KPIs to ensure alignment with strategic goals, check employee feedback to refine processes, algorithms, or integrations, and provide our client with access to technical teams to incorporate expert recommendations on features that could add value to your operations and increase ROI.

Obstacles in Embracing AI for the Logistics Industry

Advanced technologies offer a powerful toolkit for transforming logistics companies, but significant challenges can impede their adoption. Let’s explore some of the possible roadblocks of combining logistics and artificial intelligence.

Challenges Regarding Data Quality and Accessibility

Artificial intelligence in logistics industry feeds on high-quality data. However, it is not always possible to get one. It is reported that only 35% of CDOs feel they have enough resources for acquiring relevant and clean data. Logistics businesses may struggle with inconsistent data formats, where information from suppliers, warehouses, or transportation providers, may not be standardized, hindering seamless integration. Another challenge is incomplete datasets like missing information that can lead to inaccurate AI models and unreliable results.

To resolve data quality issues, our team typically implements customized ETL pipelines to clean and standardize data. For that, we apply advanced techniques to fill gaps in incomplete datasets, and integrate real-time data from different sources into centralized platforms. At the same time, we take care of data accessibility by securing access protocols, which contribute to seamless connectivity and collaboration.

Serhii Leleko

AI&ML Engineer at SPD Technology

“To ensure AI thrives on high-quality data, logistics companies can collaborate with industry partners to develop standardized data formats across the board. Additionally, implementing processes to scrub existing data sets for inconsistencies and missing information can help to ensure its cleanliness.”

Significant Implementation Expenses

In 2023, worldwide spending on AI systems was estimated at 154 billion U.S. dollars across all industries. This statistics indicates that AI technology and infrastructure require substantial upfront investment. Smaller logistics companies may find it as the greatest challenge as they operate with tighter budgets.

In this case, we usually suggest making one step at a time and implementing AI-driven logistics projects gradually. Starting with high-impact projects first will allow you to reduce upfront investments, avoid costly mistakes and, what’s important, see the added value before scaling up. In addition, we suggest starting with cost-efficient technologies like cloud-based platforms to eliminate the need for expensive on-premise infrastructure.

Integrating with Current Systems and Scalability Issues

The integration of legacy systems with AI is some of the common challenges of AI in logistics due to the outdated nature of systems’ architectures, limited compatibility with modern technologies, and a lack of flexibility to accommodate AI-driven processes. Not only will the integration be time-consuming, but also technically complex as businesses will need to bridge the gap between old systems and advanced AI solutions.

We navigate the shift from legacy systems to advanced platforms that support AI for logistics thanks to modular integration or transferring your system to cloud platforms for ensuring enough capacity to process data. Our expertise involves designing scalable systems with AI capabilities for companies that seek expansion.

SPD Technology delivered a solution for B2B Intelligence Services that handles growing volumes of data without sacrificing performance and automates document processing. As a result, the platform allows the company to increase operational efficiency by 3 times and reduce operational costs by 5 times.

Proficient Talent Shortage

Implementing and managing AI in logistics requires skilled professionals with expertise in data science, machine learning, and industry-specific operations. Yet, it is reported that 68% of executives find it difficult to hire qualified personnel.

We believe that training programs are a must for logistics companies to help their employees gain AI/ML skills and foster a culture of adaptability within the company. Our team is always ready to arrange workshops or meetings to share customized training programs focusing on both technical skills, such as data modeling and AI integration, and operational insights.

Another solution to this challenge is hiring external expertise. At SPD Technology, we completed a number of projects for logistics and can combine our industry experience with AI/ML skills to help you address specific complexities of your system.

Consider Professional AI Implementation Services for Logistic Companies

Logistics and artificial intelligence are a powerful duo that brings a wealth of benefits to the industry, yet its implementation requires thorough planning, and execution. It might be challenging for logistics companies to navigate this change. This is where the help of a trusted vendor can help to meet the unique needs of the logistics industry.

Why Is a Professional Approach Wise?

Our team combines its technical expertise with the deep understanding of logistics to help companies incorporate AI into supply chain, predictive maintenance, inventory management, warehouse processes automation and other areas.

- Expertise and Specialization: Professionals have specialized knowledge in developing custom AI solutions and experience in logistics related projects to know how to address the specific nuances of the industry with advanced solutions.

- Access to Advanced Tools and Technologies: AI specialists have access to cutting-edge AI platforms, tools, and frameworks to find those that will suit your project best without the need for increased investments.

- Focus on Core Business: AI experts handle all the technical complexities of AI implementation while you can focus on your operations, strategy, and creative tasks.

- Scalable and Future-Proof Solutions: Our AI/ML development services are focused on designing AI systems with scalability in mind to accommodate the future growth of your operations and keep your business competitive.

Why Turning to SPD Technology?

Here, at SPD technology we combine our expertise with your unique requirements to set up AI for transportation and logistics and, thus, increase your ROI and reduce operational costs. We do this thanks to:

- Proven Expertise in Logistics AI: We have a track record of delivering AI solutions specifically for the logistics industry. Our solutions address real-world challenges with measurable results.

- End-to-End Support: Our services encompass needs assessment, system design, implementation, integration, and maintenance. We complete each of these phases with precision and alignment to business objectives.

- Scalable and Customized Solutions: Our team designs modular AI systems that integrate seamlessly with existing logistics platforms, capable of scaling over time, and provides specific features for your business.

- Collaborative Approach: Our specialists prioritize collaboration with clients when setting up AI in logistics industry. We work closely with stakeholders to understand unique needs and challenges.

- Cost-Effective and Efficient Delivery: Thanks to our expertise and access to advanced tools, we deliver solutions efficiently, eliminating costs associated with delays.

SPD Technology Expertise in AI for Logistics Industry

Our team quickly embraced AI and ML from the onset of these digital technologies and has a track record of projects in logistics gained over 19 years in the market. So, in case you need a hand in setting up AI for transportation and logistics, we combine our expertise in AI development and data analytics services to deliver top-notch solutions.

For our client HaulHub, the company operating in the transportation niche, we delivered a business intelligence application capable of robust data analysis. Our team worked on:

- Centralized Data Lake: We established a data lake to serve as a central repository for all of HaulHub’s data. This allowed for seamless data analysis across the organization.

- Enhanced Data Availability: Our team utilized techniques like data denormalization, efficient caching mechanisms, and optimized database indexing to ensure HaulHub’s data was readily available for analysis.

- Seamless Data Integration: We utilized AWS Database Migration Service (DMS) to streamline data integration from various sources. Moreover, custom Extract, Transform, Load (ETL) processes were implemented to transform raw data into a structured, relational format readily accessible for analysis.

Thanks to our efforts, HaulHub obtained a robust data processing solution capable of processing millions of analytical data points, delivering smooth performance with a response time of less than 2 seconds.

Another project for HaulHub we completed was centered on AI/ML development. Our team integrated several AI models into the company’s system to ensure such functionalities as image processing, report generation, data extraction and classification, and chatbot functionalities.

During the project, we leveraged:

- OpenAI ChatGPT for tasks involving NLP for generating a chatbot’s responses to user queries and understanding contextual data.

- WS Bedrock Claude for tasks like summarization and document comparison for drafting reports.

- AWS Bedrock Titan for image, multimodal, and text models providing capabilities of content generation, image processing, search, and recommendations.

- AWS Bedrock Jurassic for text generation tasks, including question answering, text generation, and summarization.

Conclusion

If you are wondering: “How is AI transforming the logistics industry?”, we reply that the role of AI in logistics lies in saving money and increasing operational efficiency. This relatively new yet extremely powerful technology optimizes multiple logistics processes, including route planning, inventory management, maintenance predictions, demand forecasting, warehouse automation, supply chain management, fraud detection, customer support, and real-time vehicle monitoring. With all that optimization, businesses receive better operational efficiency, reduce negative impact on the environment, minimize expenses, and elevate customer satisfaction.

Despite the positive impact of AI on logistics, companies may wait with its adoption due to significant challenges. Data quality and accessibility, high implementation costs, lack of skilled personnel, and complex integration with existing systems are some of the most pressing obstacles for using AI in this domain. However, to overcome these problems, businesses can apply a phased approach to adoption, leveraging cloud-based solutions, investing in training, and potentially partnering with AI experts.

Ultimately, artificial intelligence in logistics industry transforms businesses for the better and that is why this technology is worth trying despite challenges. You can always reach out to us to leverage our industry expertise and deep AI/ML knowledge to support your AI adoption.

FAQ

Can AI Help With Last-Mile Delivery?

Yes, AI can significantly enhance last-mile delivery by optimizing routes, predicting delays, and automating dispatch decisions. It reduces delivery times, improves customer satisfaction, and lowers operational costs for logistics and transportation companies.

Is AI Replacing Human Jobs In Logistics?

AI is changing, not entirely replacing, human jobs in logistics. While AI in logistics automates repetitive tasks, it also creates new roles in AI oversight, data analysis, and system management, requiring upskilling rather than total workforce reduction.

Will AI Make Logistics Boringly Perfect — Or Even More Frustrating?

Logistics AI could streamline the industry to near perfection, minimizing errors and delays. However, poor implementation or overreliance may create new inefficiencies and frustrations. The key lies in balanced integration with human oversight and adaptability.