Artificial intelligence’s transformative impact is now a coveted goal for businesses across industries, and the food industry is no exception. In this sector, artificial intelligence plays a crucial role in ensuring food safety and quality control, forecasting demand, minimizing food waste, streamlining food production and supply chain processes, and boosting sales, among other applications. Its widespread adoption continues to grow, with its usage expected to expand further in the coming years. Precedence Research states that the AI in food and beverages market is anticipated to grow from $8 billion in 2023 to $214.62 billion by 2033.

Such a huge projected market growth raises several questions. What drivers make companies adopt machine learning and artificial intelligence in the food industry? Are there real-world success stories of implementing AI in this domain? What food business challenges can AI solve? This article explores the answers to these questions.

Pressing Food Industry Challenges AI Can Solve

The food industry is confronted with a multitude of critical food security and production challenges that have emerged due to a combination of factors, including population growth, urbanization, climate change, and resource constraints. However, artificial intelligence helps organizations establish sustainable practices to solve these issues.

Food and Hunger

McKinsey projects that artificial intelligence will reduce food waste and unlock an economic opportunity of $127 billion in 2030. The primary drivers here are considered predictive analytics and smart inventory management. Both help the food industry by introducing AI algorithms for the analysis of historical demand data.

Thanks to predictive analytics in the food industry, companies gain the possibility to optimize demand and, consequently, production processes and minimize excessive inventory. On top of that, AI algorithms identify surplus food within the supply chains and promote its redistribution to areas of need.

Water Shortage

A solution to water shortage challenges in the food sector can be AI-enabled precision irrigation systems equipped with sensors and data analytics. These systems monitor soil moisture levels, weather patterns, and crop water requirements in real-time, which helps to adjust watering schedules and minimize water wastage and maximize crop yields.

Another application of AI in the food service industry is leak detection that reveals failures in irrigation infrastructure. Once breakage is detected, food companies can focus their efforts on repair works, saving as much water resources as possible.

Crop Diseases

Artificial intelligence and machine learning for the food industry powers disease detection algorithms for food safety monitoring and prevention of crop contamination. This can be done by computer vision-powered image analysis and precision diagnosis to detect signs of crop diseases at an early stage.

AI algorithms can identify discoloration, spots, wilting, or abnormal growth patterns that indicate specific diseases and enable food companies to implement targeted treatments or disease prevention and management measures.

Climate Change Resilience

AI technology with climate modeling combines historical climate data with predictive analytics to forecast future climate trends and their potential impacts on agriculture. This helps the food industry with climate modeling and predictive analytics, which simulate climate scenarios and suggest companies to adjust planting schedules, crop selection, and incorporate measures to prevent climate-related risks.

More assistance in terms of improving overall crop health comes from AI-generated data insights. They enable informed decision-making concerning disease management, resource allocation, and planting practices.

The Role of AI in Building a Greener and Safer Food System

Artificial intelligence in the food industry has not only refined agricultural processes and made the work environment safer, but it’s also a significant win for our planet. This innovative technology is quietly reshaping how we produce and consume food, which unlocks benefits for everyone from farm to table and beyond.

How Is AI Transforming Food Safety and Quality Control?

AI technology in the food industry introduces new algorithms and models, more powerful integrations, and enhanced capabilities that put safety on a whole new level. Below are some of the AI-driven safety improvements.

- Image-based inspection. High-resolution cameras paired with deep learning models now flag foreign objects, mold, off-colors, or mis-labels on processing lines in milliseconds. This means far faster, more consistent checks than human inspectors can perform.

- Predict-and-prevent analytics. Networked temperature, humidity, and vibration sensors stream into cloud AI platforms that warn operators the moment the cold chain drifts or a filler nozzle vibrates outside spec. Microsoft reports that generative AI agents built on these data cut recall risk by surfacing anomalies hours earlier and maintain optimal food safety standards.

- AI-native compliance and recall orchestration. Some LLM tools continuously scrape global regulations, incident alerts, and scientific journals. They automatically map rules to each SKU and forecast changes months in advance. During an incident they can trace lot codes, draft recall press releases, and generate evidence packs for regulators in minutes instead of days.

- Sanitary robotics and smart maintenance. Vision guided robotic arms keep human hands, and thus potential pathogens, away from open product, while ML maintenance models schedule clean-in-place cycles or part swaps just before hygiene risks arise, eliminating both downtime and contamination.

What Role Does AI Play in Sustainable Food Production?

Beyond its role in refining agricultural processes and enhancing workplace safety within the food industry, AI emerges as a powerful ally for our planet. The factors below contribute to sustainable agriculture.

- Climate-smart farming. On the field, sensor networks, satellite imagery and ML models prescribe exactly when and where to irrigate, fertilise or spray. Trials show water use can drop by up to 30% and fertilizer by about 20% without hurting yield, while predictive analytics that steer input choices shrink farm-level carbon footprints by 10-20%.

- Energy-efficient controlled environments. Deep reinforcement learning controllers now tune lighting, ventilation and CO₂ in vertical farms and greenhouses. Cornell engineers reported that optimised algorithms trimmed energy demand for indoor lettuce by roughly 25%, which turns high-intensity systems into credible low-carbon suppliers of year-round produce.

- Cutting waste and extending shelf life. Downstream, retailers pair ML demand forecasting with “digital twins” that estimate a product’s real freshness rather than relying on conservative expiry dates. Pilots with Afresh and Shelf Engine drove a 14.8% cut in store-level food waste, and virtual shelf-life models further curb premature discards.

- Tracking and shrinking supply-chain emissions. Enterprise platforms such as CO₂ AI leverage the use of automation in the food industry to match millions of activity records with emission factors. This gives companies near real-time Scope 3 footprints and reduction scenarios, while startups like Treefera combine satellite and drone imagery to flag deforestation or other first-mile risks in crops such as coffee and palm oil.

AI in Food Production: How It Helps with Cycle Optimization?

Food manufacturers use artificial intelligence technologies to improve almost every food production phase, from planning to distribution.

Planning and Forecasting

Problem: Inaccurate demand forecasting causes excessive food production.

Solution: AI/ML algorithms leverage advanced statistical models, such as time series analysis and machine learning algorithms like regression and neural networks. These algorithms unlock the business impact of big data by analyzing extensive datasets comprising historical sales data, market trends, and external factors such as weather patterns and holidays.

Also, through the application of predictive analytics, including autoregressive integrated moving average and long short-term memory models, artificial intelligence adapts production plans in real-time to accommodate consumer demand fluctuations. Employing advanced optimization algorithms like genetic algorithms and gradient descent, the specialists in food production optimize inventory levels and reduce waste, guaranteeing efficient resource allocation and maximizing profitability.

Want to know more about demand forecasting with machine learning?

Learn all the details in our featured article!

Crop Management

Problem: Misallocated resources, such as water, fertilizers, and pesticides, create damage to the environment and waste.

Solution: Thanks to the use of machine learning in the food industry, it has become possible to enhance food equipment with precision techniques that collect and analyze data from soil sensors, meteorological stations, and drone-based sensing arrays. Machine learning algorithms like decision trees and support vector machines extract insights from this data and provide information about soil health, moisture dynamics, and pest presence.

Harvesting and Yield Optimization

Problem: Labor-intensive harvesting and crop yields reduce productivity.

Solution: Companies can opt for computer vision development services to build systems for monitoring harvesting. Deep learning models like convolutional neural networks and object detection algorithms, which drive computer vision systems, allow AI systems to pinpoint ripe produce, promoting accurate harvesting practices.

Serhii Leleko

AI&ML Engineer at SPD Technology

“Guided by reinforcement learning algorithms, artificial intelligence optimizes harvesting strategies in real-time, factoring in variables such as crop density, ripeness, and field conditions. Continuously refining their techniques, these algorithms adapt on the fly to maximize yield while minimizing damage to crops. Powered by edge computing, AI also processes sensor data instantaneously, facilitating agile decision-making and elevating production efficiency to unprecedented levels”.

Post-Harvest Handling and Food Processing

Problem: Poor food processing and storage cause spoilage and waste.

Solution: AI-enhanced systems that connect with IoT sensors and radio-frequency identification tags aids in overseeing storage equipment in real-time. Leveraging sophisticated deep learning models such as recurrent neural networks and generative adversarial networks, these systems scrutinize sensor data streams, detecting anomalies with machine learning and preemptively predicting equipment failures.

Food Packaging and Labeling

Problem: Misleading food labeling can lead to inaccurate food sorting.

Solution: AI-enabled image recognition systems enhanced with convolutional neural networks assist in sorting food packaging and labeling. In addition to image recognition, AI technology in the food business can be powered by natural language processing for quality control of the information presented on wraps, cans, bags, bottles, etc. NLP analyzes text on packaging, detects and flag issues for further resolution.

Distribution and Logistics

Problem: Unoptimized transportation routes and inventory management cause delays and increased costs.

Solution: The role of artificial intelligence is crucial when it comes to planning by optimizing transportation routes and enhancing inventory management. Reinforcement learning and evolutionary algorithms allows AI in the food market to find optimal routes for delivery, while k-means clustering and neural networks allows forecasting any demand fluctuations. These AI algorithms and ML models bring precision for inventory management across different distribution channels.

Curious about how AI is shaping the future of retail?

Dive into our article for all the insights!

Quality Control and Inspection

Problem: Manual inspection causes errors, compromising food quality.

Solution: Computer vision powered by deep learning algorithms and object detection models to inspect food products for defects, contaminants, or anomalies. Through the application of transfer learning methods and data augmentation, these systems are meticulously trained on diverse datasets to provide robust performance across a spectrum of product varieties and environmental conditions.

Interested in delving deeper into the applications of AI and ML in manufacturing?

Explore our expert article on this topic!

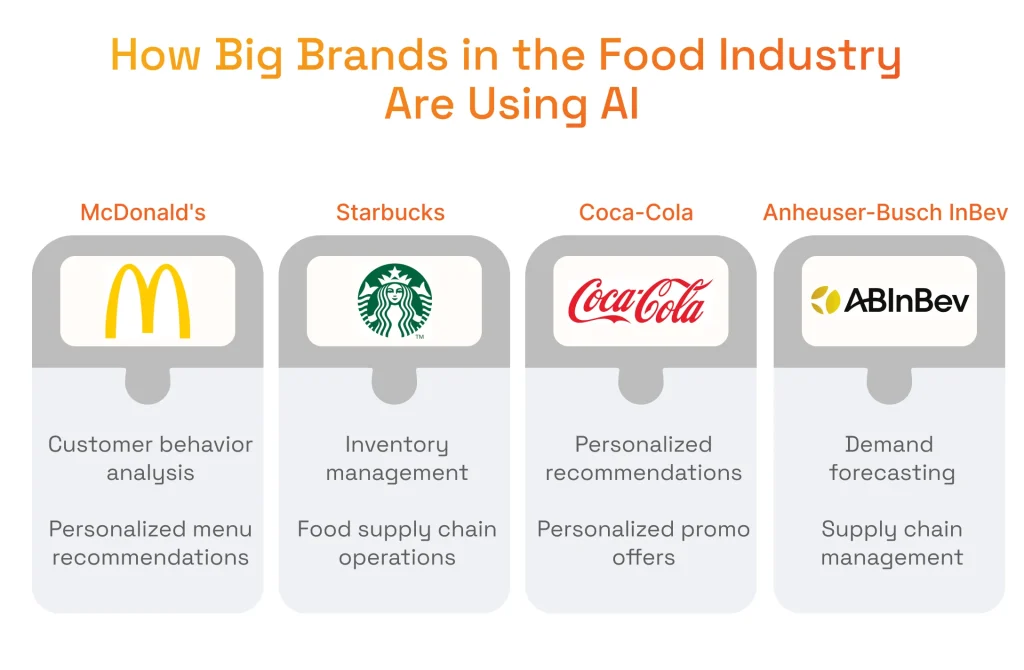

How Big Brands in the Food Industry Are Using Artificial Intelligence and Machine Learning?

Due to rapid technology evolution, food companies are swiftly integrating cutting-edge technologies into their operations, embracing the prowess of artificial intelligence. They show exceptional examples of AI applications that can be adopted by many other companies for improved operations and customer satisfaction.

McDonald’s

McDonald’s integrated AI in advertising screens equipped with temperature and light sensors. The screen can be placed on bus stops or along the street and set up to show specific promo based on both temperature and time of the day. As an example, the ad can show breakfast meals in the morning or ice cream offerings in the hot weather.

Starbucks

Starbucks leverages AI technologies to optimize both customer experiences and staff operations. When it comes to improving customer satisfaction, AI helps Starbucks analyze sales data and find similarities in seasonal fluctuations or holiday demand spikes to keep an optimal stock for the right assortment. When Starbucks needs to improve operational efficiency, AI algorithms unlock the power of predictive analytics for demand forecasting and allows optimization of food supply and inventory operations.

Coca-Cola

Coca-Cola shows several applications of ML in the food industry, by leveraging this technology for marketing, sales, and food supply chain management. One of the most notable examples is the analysis of social media information, particularly 120,000 pieces of content on a regular basis, to understand the demographics, behavior and preferences of its customers.

Anheuser-Busch InBev

Anheuser-Busch InBev harnesses the potential of AI technology to optimize its brewing and supply chain management. A notable application is the utilization of AI-driven predictive analytics to analyze sales figures, market trends, and external variables, and forecast demand across diverse locations and time frames.

Using AI and ML-Powered FoodTech Solutions in Everyday Life

Artificial intelligence and machine learning have the potential to significantly enhance our everyday lives. From personalized nutrition recommendations to optimizing household chores and managing daily schedules, ML/AI technologies offer a wide array of applications that cater to individual needs and preferences.

Personalized Nutrition Recommendations

AI and ML technologies are revolutionizing nutrition by providing personalized recommendations tailored to individual needs and preferences.

- AI algorithms analyze user data to tailor personalized recommendations based on dietary habits, health conditions, and goals.

- Predictive analytics forecast how foods impact health outcomes, promoting informed dietary choices and helping to move from junk food to healthy food products.

- AI technology creates personalized meal plans tailored to users’ goals, whether it’s weight loss, muscle gain, or simply switching to healthy foods.

- Continuous learning enables AI systems to refine recommendations over time, ensuring relevance and effectiveness.

Smart Kitchen Appliances

Kitchen equipment is getting smarter thanks to AI and ML capabilities, which optimize resource usage and offer individualized culinary experiences.

- AI in the food industry allows upgrading kitchen appliances into intelligent devices by integrating sensors, cameras, and connectivity features to understand and respond to users’ needs.

- Smart kitchen appliances suggest recipes based on consumer preferences, ingredient availability, and dietary goals, utilizing data from recipe databases and user feedback.

- Artificial intelligence with predictive analytics anticipate cooking times and temperature adjustments by analyzing historical recipe data and user interactions.

- Smart appliances refine recipe recommendations and cooking techniques over time by learning from user interactions and feedback.

Food Waste Reduction

Artificial intelligence in the food and beverages market helps reduce food waste by optimizing meal planning and grocery shopping processes.

- AI meal planning apps optimize meal plans by analyzing ingredient availability, expiration dates, and user preferences to reduce waste.

- Artificial intelligence grocery platforms recommend optimal quantities based on past purchases and household size, minimizing overstocking and food spoilage.

- AI also helps to reduce food waste, when it adapts to user preferences over time by analyzing interactions and feedback, refining suggestions, and providing personalized tips.

Recipe Recommendation and Cooking Assistance

AI-powered platforms provide users of all skill levels with real-time help and personalized recipe recommendations.

- ML algorithms analyze user data to understand food products preferences and skill levels, tailoring recipe recommendations accordingly.

- AI recipe recommendation platforms generate personalized suggestions aligned with users’ preferences and dietary goals.

- AI cooking assistance tools offer step-by-step guidance and real-time feedback to help users achieve optimal results.

- AI in the food industry continuously improves recommendations based on user interactions and feedback to better meet users’ needs over time.

The Challenges of Using ML and AI in the Food Industry

Although AI technologies offer immense potential for the food industry, there are still several obstacles in the way of fully leveraging AI and ML. Let’s explore these challenges, and ways to overcome them.

Data Quality and Availability

Crop monitoring, ensuring food safety, supply chain management in the food industry are the areas where collecting high-quality data is one of the most complex tasks. To facilitate this process, we establish robust data collection protocols. They outline the specific methods, procedures, and standards for data collection methods frequency, quality standards, storage and management, analysis and reporting. This guarantees integrity and accessibility of data, while supplying the food industry with information businesses can rely on.

While developing a tool to automate paperwork and invoice processing for our client, we encountered a challenge due to the absence of labeled data and the presence of highly imbalanced data. To tackle this issue, we introduced an ML-powered solution for complete invoice processing automation in the food industry. This tool, delivered through an API, predicts the master service code of an item in an invoice based on its textual description. Moreover, this solution enables time savings and reduces human error, all while ensuring compliance with regulations.

Complexity and Variability of Food Systems

Setting up AI systems to understand how food is grown, processed, and delivered requires a multifaceted approach with numerous factors taken into account. Moreover, it is difficult to train ML models based on the information on those processes. The complexity adds up because the absence of standardized data formats, protocols, and practices across diverse segments of the food industry poses obstacles to model development and deployment. We address these challenges by implementing robust interoperability solutions and have a proven track record of seamlessly integrating disparate data sources and systems.

Regulatory and Ethical Considerations

The integration of AI in the food industry raises a ton of regulatory and ethical concerns, encompassing aspects such as privacy, security, fairness, and accountability. We navigate these regulatory landscapes with meticulous care, ensuring compliance with stringent data protection regulations and ethical guidelines while truly harnessing the potential of AI and ML.

Serhii Leleko

AI&ML Engineer at SPD Technology

“Key concerns in the food industry include safeguarding consumer privacy and protecting sensitive data collected through AI systems. Ensuring the security of AI-driven processes and algorithms is vital to prevent unauthorized access or malicious manipulation of data. Moreover, there’s a pressing need to address issues of fairness and bias within AI algorithms, particularly in decision-making processes that may impact both individual consumers and food businesses”.

Skills Gap and Talent Shortage

Successful implementation of AI in the food industry hinges on access to specialized skills and expertise in data science, machine learning, and domain knowledge. However, the industry grapples with a notable shortage of qualified professionals possessing the requisite technical proficiencies and domain-specific insights. To bridge this skill gap, companies need to foster collaboration and provide training for their employees.

At SPD Technology, are offer exceptional data science and AI and Machine Learning development services. With a dedicated team of domain experts, we are capable of addressing the unique challenges and opportunities in the food industry. Our machine learning engineers strive to push the boundaries of AI innovation in every project they take on, empowering food tech businesses to harness the full potential of intelligence technologies for transformative growth.

Choosing the Right Approach to Implementing AI/ML in the Food Industry

AI/ML technologies are unlocking new opportunities for growth and efficiency, solving critical industry challenges, as well as serving as a deciding factor in the emergence of entirely new products and services. However, the key to success lies in the implementation, as businesses have a choice to develop the technology internally or find an external provider.

In-house or Outsourcing?

Both approaches have their advantages and challenges, so the right choice depends on specific needs, available resources, and the long-term strategic goals of your organization.

In-house Development

When you choose to set up an AI/ML team internally, you will have the greatest amount of control over the development and implementation process, since your development team will be an integral part of your organization. At the same time, this approach requires massive upfront investments, finding and hiring rare specialized talent, as well as investing in their continuous education and technology expertise growth.

If your organization is big enough to spend a large chunk of the budget on AI/ML and have time to wait for this long-term investment to blossom, forming an in-house team may be a suitable option. However, for smaller companies that are just considering adding this innovation to their processes, the costs and risks of forming their development team may be too high.

Outsourcing AI/ML Expertise

Partnering up with an external AI/ML development and data analytics company for your AI/ML project is a great way to tap into specific expertise, without the hiring and management hassle. With a trusted vendor, you will be able to quickly implement pivotal solutions, leverage cutting-edge technology stacks, and reduce the development time and risks. Additionally, outsourcing allows flexibly adjusting the human resources needed for your solution development, scaling your outsourced team up or down depending on the current stage of the product maturity.

The biggest drawback of outsourcing is the possible lack of understanding of the Food Industry’s intricacies and the specific needs of your organization, that some vendors might have. AI/ML solutions work as a true transformative power for an organization only when they are closely aligned with its specific operational challenges and business goals, so choosing the development partner always require careful consideration of the company’s competencies

Why Choose Us for Your Next AI/ML Project?

We, at SPD Technology, stand out as an AI/ML company with a deep, cross-industrial experience in developing groundbreaking solutions for the leaders in their respective markets. As for the food industry, we understand its unique operational challenges, regulatory requirements, and market trends, so that’s why our projects end up impactful and future-proofed.

AI/ML services that are included in our software product development process span from initial consulting and forming a data strategy, to custom model development and seamless integration. We will build a modern, end-to-end solution for your organization that will target all areas you require, including but not limited to supply chain optimization, food safety enhancement, and customer experience improvement.

Deeply understanding business hurdles, our experts prioritize delivering transparent and explainable solutions without adding unnecessary complexity. We always drive measurable business results and work for the highest return on investment, while implementing technologies that shape the future of the Food industry. On every level, we ensure that your AI/ML solution will be locked in with your data strategy and core business objectives.

SPD Technology has been building long-lasting partnerships with our clients for over 18 years, as we grow with the businesses of our clients. We will make sure that your investments in AI/ML solutions will turn into a massive success, as we will support your project as long as needed, scaling it following the growing business demands.

How We Helped Food Companies to Implement AI/ML

Let our success stories speak for themselves. Here are some of our latest use cases for delivering AI/ML solutions and driving innovation for our clients.

AI-Powered Demand Forecasting Solution for a Food Distributor

Business Challenge

Our client has been a notable market player in food distribution for many years, creating an extensive product portfolio along the way. With the seasonal fluctuations, changes in market trends, and customer behavior, the client constantly suffered from missed opportunities and increased operational costs due to overstocking or shortages. The client opted for our custom software development services to create a versatile demand forecasting solution capable of handling large volumes of data and taking holidays and weather patterns into account.

SPD Technology’s Approach

Our team conducted a thorough analysis of the historical sales data of our client, aligning it with several external factors that made an impact on demand. We decided to use a hybrid model that included multiple time series forecasting techniques and machine learning algorithms. In particular, data ingestion and preprocessing were used, combined with predictive modeling using ARIMA, XGBoost, and LSTM. The system was designed to be scalable, as the client continued to add products to the portfolio. We integrated the solution into the client’s infrastructure via our custom API that allowed stakeholders to have access to predictions in real time and build a user-friendly UI/UX dashboard.

Value Delivered

- 15% Cut of Excess Inventory: Thanks to demand prediction capabilities, our client was able to minimize overstocking and significantly lower operational costs.

- 10% Sales Increase: Our solution helped the client to make more informed decisions on product availability, which resulted in additional profits.

Overall, we delivered a scalable, high-performing demand forecasting solution that was able to optimize inventory management for our client and exceed the initial expectations.

AI-Driven Quality Control System for a Food Manufacturing Company

Business Challenge

Our client is a food manufacturing company with some major quality control issues in its production lines. They hired our dedicated software development team to build an AI-powered quality control system able to detect packaging errors and product inconsistencies in real-time.

SPD Technology’s Approach

After a deep analysis of the client’s production flow, we decided to go with a computer vision-based solution combined with machine learning algorithms. We worked closely with the client to collect a large dataset of images from the production lines, capturing both defective and non-defective items. After that, we built a custom image recognition model capable of identifying common defects. The model was developed to train and improve its accuracy over time and was deployed directly on the production line, integrated with cameras and sensors that captured images of every product as it passed through.

Value Delivered

- 20% Production Efficiency Increase: Our solution automated quality control, reducing the need for regular manual inspections and leading to a boost in cost-effectiveness.

- 15% Annual Production Costs Decrease: After the first successful year of operation, our solution has proven to reduce the number of defective products and recalls, leading to major savings for the client.

Ultimately, we delivered a market-leading, AI-powered quality control solution that increased efficiency, and enhanced overall product quality, leading to higher profits for the company.

Conclusion

The integration of artificial intelligence and machine learning represents a pivotal moment in the food industry, offering innovative solutions to pressing challenges and driving sustainable growth. AI and ML are transforming food safety, food production processes, waste reduction, and sales optimization across the sector.

The integration of AI and the food industry promises to facilitate accurate demand forecasting, inventory and supply chain management. It also empowers food manufacturers to address climate-related risks and enhance sustainable agricultural practices. Additionally, AI and ML offers personalized nutrition recommendations, smart kitchen appliances, and cooking assistance platforms for consumers and restaurants, promoting healthier lifestyles.

However, challenges such as data quality, complexity of food systems, regulatory compliance, and skills shortages persist. Collaborative efforts are needed to overcome these hurdles and foster an environment conducive to ML and AI in the food industry innovation.

Effective utilization of AI and ML technologies can propel the food industry towards a sustainable future that is technologically advanced, environmentally conscious, and socially responsible. Our AI/ML software developers would be glad to support your food & restaurant business along the path of intelligent transformation!

FAQ

Which Companies Are Leading in AI-Driven Food Innovation?

McDonald’s uses AI in the fast food industry to change promos based on temperature and time of day, while Starbucks uses predictive analytics to forecast demand and optimize inventory. Other companies that use AI include Coca-Cola, Anheuser-Busch InBev as well as Kraft Heinz, Unilever, Brightseed, Ai Palette, Nestlé’s Henri platform, Ocado Technology, and IBM Food Trust. The use cases are spanning plant-based formulations, digital twins, bioactive discovery, predictive trend analytics, and blockchain-enabled transparency.

How Do AI-Powered Robots Work in Food Packaging and Logistics?

Using robots enhanced with AI in the food service for packaging enables computer vision to identify products, path-planning algorithms to pick and place items, swarm coordination to route totes. They accelerate assembly, reduce waste, and improve traceability.

How Is Machine Learning Used in Food Product Development?

ML mines ingredient, sensory, and market data to model flavor chemistry, predict acceptance, and optimize formulations. This helps developers prototype digitally, shorten iterations, personalize nutrition, and slash costs and timelines.