The construction industry has long struggled with poor planning, budget overruns, and complex regulations. All of them caused project delays and lower-than-expected returns on investment.

Data analytics can solve many of these problems by making project management smoother and processes more efficient. In fact, 45% of construction companies already use basic analytics, while another 45% are still working to integrate these tools across their projects.

However, to join the ranks of companies that have successfully implemented data analytics in construction, a professional approach is essential. This article provides the ultimate overview of the opportunities data analytics creates for the construction industry, along with the proven ways to leverage them strategically.

The Potential of Big Data Analytics in Construction Industry

Regardless of the industry, Big Data means big opportunities. When lots of information is properly analyzed, extensive data sets can uncover valuable patterns, trends, and insights. In construction, Big Data includes everything from financial records and project schedules to inspection results and equipment usage.

Let’s explore why analyzing this data is so important.

The Transformative Benefits of Using Construction Data Analytics

Leveraging Big Data analytics in the construction industry is invaluable for its potential to improve planning, scheduling, budgeting, and numerous other processes. Below are the main advantages of using it.

More Efficient Project Planning and Scheduling

Effective planning is fundamental to any construction project’s success, and data analytics is critical here. Just consider: 37% of such projects miss deadlines or exceed their budgets, according to the KPMG survey.

However, with construction data analytics, companies can study historical data on past projects — like timelines, resource usage, worker productivity, and other factors — to create more accurate schedules and avoid costly setbacks in their future initiatives.

To illustrate this more vividly, companies may identify repetitive tasks that cause delays or flag potential project slowdowns due to weather conditions or supply chain disruptions. Ultimately, they’ll be able to adjust plans on the go.

More Accurate Project Cost Estimation and Budgeting

Estimating costs more precisely is one of the greatest advantages of construction data analytics. It’s even more critical when you learn that 14% of all rework in construction globally is caused by “bad” data — either inaccurate or incomplete.

Poor data quality and cost miscalculations may result in budget overruns, often due to rework, material price changes, or labor shortages. Data analytics services help avoid these issues by letting companies set realistic expectations for project costs and profitability.

For example, construction companies can predict potential project cost increases from rising material prices. All in all, data analytics is the way to achieve financial predictability and allocate resources better.

Dmytro Tymofiiev

Delivery Manager at SPD Technology

“Accurate cost estimation is no longer a guessing game. With data analytics, construction companies can allocate their budgets more reliably, counting large-scale materials and the smallest details like individual screws alike.”

Careful Environmental Impact Assessment and Optimization

Data analytics is also critical for achieving sustainability and about 71% of construction companies surveyed by Autodesk have already increased their sustainability investments.

By using data analytics, environmentally conscious construction businesses do more than just benefit the planet. They also save costs through reduced waste and energy consumption.

For instance, with data analytics tools, companies can evaluate the environmental impact of different construction materials by analyzing their lifecycle — from production to disposal — and identifying the materials with lower carbon footprints. Plus, they can track energy consumption patterns on the construction site, optimizing machinery, lighting, and HVAC systems for reduced energy usage.

Improved Safety and Risk Management

Ensuring safety on construction sites is another benefit of data analytics. However, only 14% of companies surveyed by FMI and Autodesk have fully seen how a data strategy reduces safety incidents.

By analyzing construction data, companies can identify risks, predict potential accidents, and implement measures to prevent them, ultimately protecting the well-being of workers and the success of projects.

For example, they may evaluate patterns in worker behavior to discover unsafe practices before they lead to casualties. Or they may monitor equipment in real time to prevent malfunctions that could pose safety hazards.

Enhanced Client and Stakeholder Transparency

Finally, the business impact of Big Data and analytics tools becomes even more significant when the transparency in construction projects is ensured with its help.

According to McKinsey, the average construction company has fewer than ten employees. However, a single construction project typically relies on a large network of over 100 suppliers and subcontractors. Ensuring clear communication between all these stakeholders is the task that data analytics can help with.

For example, companies may use tools for data visualization and real-time reporting to let clients and stakeholders easily track project progress, financials, and milestones. By keeping everyone on the same page, construction firms execute projects smoothly and build stronger relationships and trust.

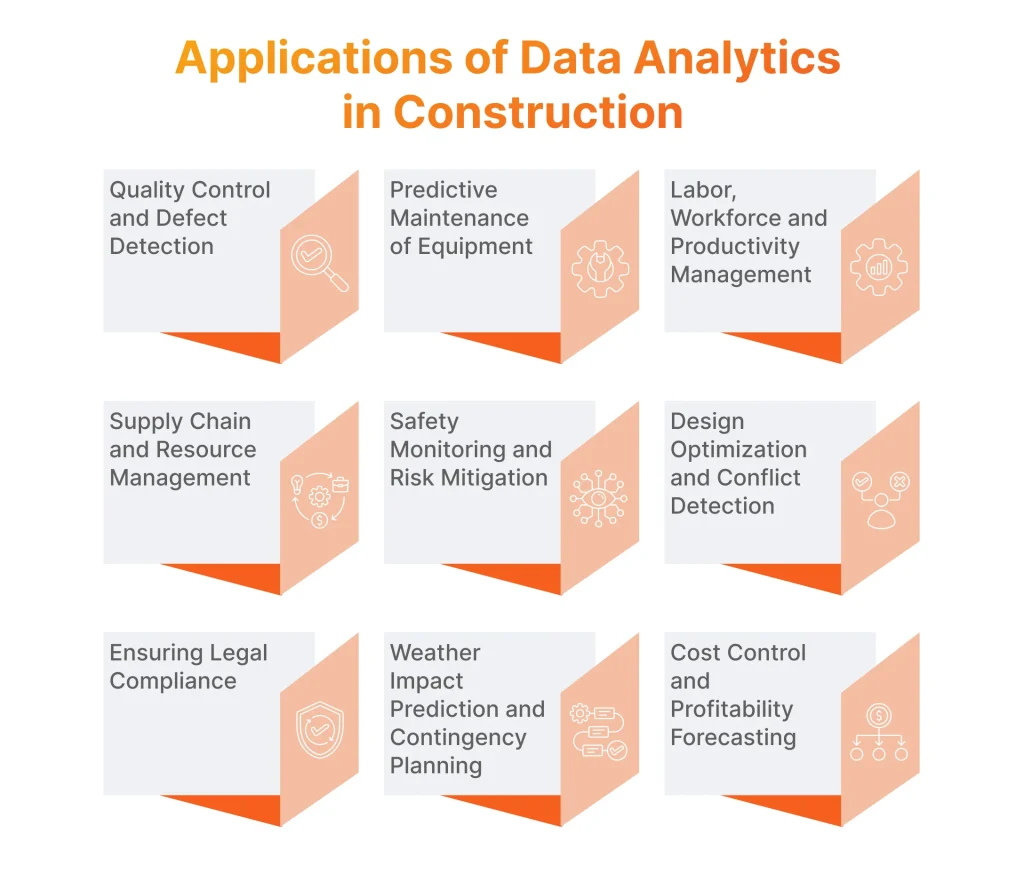

Applications of Data Analytics in Construction

With all the above mentioned advantages, data analytics isn’t just beneficial in one part of construction. You can apply it across the entire process, from planning to maintenance. Let’s explore the key areas where to use it.

Quality Control and Defect Detection

Quality is critical in construction, and data analytics can help detect defects early on. Companies can look at inspection results, sensor readings, and issue reports and compare them to the project’s specifications to ensure everything is on track. For example, our AI/ML-powered defect prevention system enables equipment inspection by collecting and analyzing data from sensors attached to it.

Predictive Maintenance of Equipment

Predictive maintenance allows companies to forecast when a piece of heavy machinery is about to break down. These forecasts can be made by studying sensor data on the equipment. Our AI-powered predictive maintenance system, for instance, focuses on monitoring and analyzing electricity consumption data to anticipate when equipment is likely to fail or require servicing.

Labor, Workforce, and Productivity Management

Managing a construction workforce efficiently is a challenging task. However, with data analytics, companies get the means to track worker productivity, optimize labor schedules, and allocate resources more wisely. For example, real-time data can show which teams are performing better and which, in turn, require more resources and attention.

Supply Chain and Resource Management

The outcomes of construction projects largely depend on materials and resources arriving on time and in the right quantities. Construction analytics helps achieve that by predicting demand, monitoring inventory, and managing suppliers. Overall, it ensures projects aren’t delayed due to missing materials and helps reduce waste by only ordering what’s necessary.

Safety Monitoring and Risk Mitigation

Data analytics tools can be used to ensure safety on construction sites. In particular, they allow companies to study historical data on accidents and near-misses to identify high-risk areas and unsafe working practices. Sensors installed within the location can also provide companies with real-time data on safety conditions.

Design Optimization and Conflict Detection

Before construction even begins, a building must first be designed. Companies may use data analytics to examine blueprints and project models for inconsistencies during the design process. As a result, architects, engineers, and construction teams will find a joint solution and deliver it smoothly.

Ensuring Legal Compliance

Construction projects must follow various regulations, from environmental laws to safety codes. Data analytics tools can help companies not to miss a single legal requirement. On top of that, automated systems can alert businesses of potential compliance issues so that they can avoid non-compliance-related fines or delays.

Weather Impact Prediction and Contingency Planning

Weather can be unpredictable. But still, construction data analytics helps prepare for its impact. It lets companies analyze historical weather patterns and real-time forecasts to determine how the weather will affect timelines and resource availability. Besides that, it allows project managers to create backup plans in case of emergencies.

Cost Control and Profitability Forecasting

Data analytics solutions also help manage project costs and predict profitability. These tools track spending and analyze historical financial data so that companies can forecast potential budget overruns and make adjustments before it’s too late. Additionally, predictive analytics in construction can be used to determine where firms are most likely to save money or where additional investment might be needed.

Technology and Tools Used in Construction Analytics

Now that you know about the possible applications of data analytics in construction, let’s discuss the techs and tools to make that all possible.

Technologies

There are several core technologies that power construction data analytics.

AI and ML

Artificial intelligence and machine learning — already adopted by 40% of construction companies — can analyze large datasets, identify patterns, and make predictions. In particular, they enable such tasks as:

- Predictive analytics to forecast material costs, pinpoint potential risks, and optimize project schedules.

- Robotic process automation development to automate repetitive tasks.

- Natural language processing to quickly analyze contracts and other documents.

Internet of Things

The Internet of Things, or IoT, creates an interconnected network of devices and sensors that can gather real-time data from construction sites. The data can help you better understand equipment performance, material usage, and worker safety.

- Drones capture aerial images for progress monitoring and defect detection.

- Wearables like smart helmets, vests, and wristbands track worker health metrics to identify safety risks, monitor fatigue, and improve overall worker safety.

Augmented and Virtual Reality

AR and VR technologies improve the construction experience by:

- Visualizing designs so that stakeholders can see projects in 3D before construction begins.

- Providing immersive training for workers.

Tools

Whether you aim to use artificial intelligence for supply chain optimization or IoT for equipment monitoring, these are the tools that can help:

Tools for Predictive Analytics in Construction Industry

Predictive analytics tools analyze historical project data to anticipate future outcomes. This allows construction companies to make proactive decisions. AVEVA is one decent example. It helps construction and industrial companies anticipate operational risks, optimize asset performance, and reduce downtime, using predictive algorithms to monitor the health and performance of equipment, and providing instant insights into current operations with its real-time monitoring capabilities.

Cloud Construction Management Tools

Cloud-based construction management tools leverage all the cloud computing infrastructure benefits — cost-effectiveness and real-time collaboration between teams, regardless of their physical location. Such solutions typically allow for project management, financial tracking, and quality assurance in a single place. Examples include Procore and Autodesk Construction Cloud.

Building Information Modelling (BIM) Tools

BIM tools like Autodesk Revit let construction teams create detailed, interactive 3D models of their projects. These models provide a comprehensive view of all project components. Such tools ultimately improve coordination among architects, engineers, and construction workers.

Data Visualization Software

Data visualization tools allow construction companies to organize their datasets into easy-to-understand visual representations. This way, they help teams monitor progress and uncover construction insights that may not be apparent in raw data alone. Popular solutions include Tableau, business intelligence and data visualization software, and Grafana, an interactive data analytics dashboard.

Enterprise Resource Planning (ERP) Systems

ERP systems integrate various business processes into one platform. The processes span from finance and procurement to logistics and sales. Common choices for construction include SAP and Odoo.

Main Considerations for Choosing the Right Construction Data Analytics Software

Having learned about the tools available, you might wonder which works best for your construction company. Selecting the right data analytics solution requires keeping the industry’s specifics in mind. Partnering with a data analytics consulting vendor for professional advice might help you make a smart choice.

But first, let’s go through the key considerations.

Project-Based Nature of Construction

The main thing to take into account is that data analytics requirements may vary from one construction project to another. It includes:

- Unique data for each project: Construction projects differ in design, location, timeline, budget, and challenges. Your data analytics solution should be able to handle these diverse datasets and offer customization to meet the specific needs of each project.

- Short-term focus: Construction projects are often time-sensitive. Choose analytics solutions that provide real-time insights, rapid data processing, and visualization to enable timely decision-making and risk mitigation.

Dynamic and Unpredictable Work Environment

Some degree of unpredictability is one of the main characteristics of the construction industry. When choosing data analytics software, pay attention to the following:

- Uncertainty factors: Construction sites are subject to weather changes, labor availability, and site conditions. Your analytics solution must adapt to these dynamic conditions and provide predictive modeling and real-time data analysis.

- On-the-fly adjustments: The ability to make quick adjustments is crucial in construction. Choose technologies that offer real-time data analytics and agile reporting to respond to emerging challenges and optimize project execution.

Emphasis on Physical Asset Management

To ensure efficient and cost-effective construction projects, you need data analytics software that makes it easy to manage the physical assets involved.

- Equipment and asset usage: Construction relies heavily on machinery and equipment. Choose analytics solutions that offer asset management, along with equipment performance monitoring and predictive maintenance.

- Wear and tear tracking: Prioritize construction data analytics software that lets you track the lifecycle of materials and equipment to ensure timely maintenance and replacement.

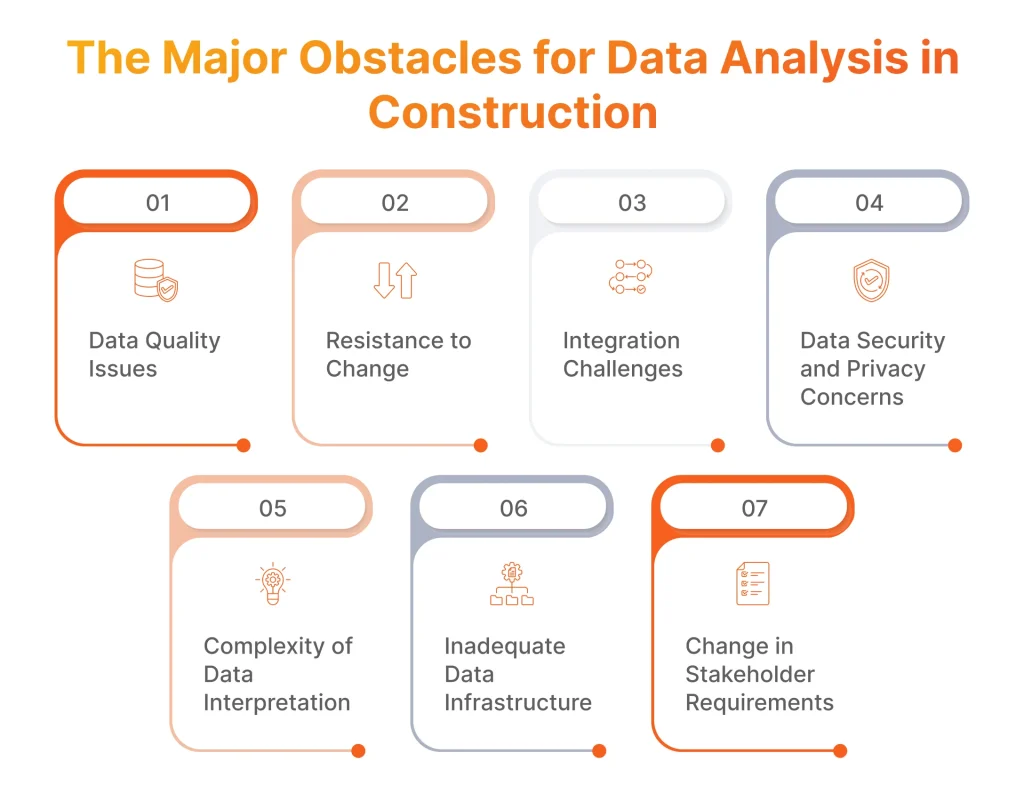

The Major Obstacles in Implementing and Leveraging Data Analytics in Construction

Besides just selecting the right construction data analytics software, it’s also necessary to be aware of the potential challenges that can arise. Let’s discuss the most common ones.

Data Quality Issues

One of the biggest challenges is the accuracy and completeness of the data analyzed. If your data is outdated, inaccurate, or incomplete, you may get unreliable insights and make poor decisions.

Dmytro Tymofiiev

Delivery Manager at SPD Technology

“Data quality can really be a make-or-break factor for construction projects. Clean, accurate data is the guarantee for better project outcomes.”

How to address it: To address this challenge, it is necessary to implement robust data validation and cleaning processes. Ensuring the software features automated quality checks and user tools for flagging and correcting data anomalies in real time is also a must.

Resistance to Change

Many construction teams may be hesitant to adopt new technologies or change their well-established workflows, especially when they’ve relied on traditional methods for years.

How to address it: Through early engagement of all stakeholders, the company will be able to identify the team’s specific concerns and needs. At the next step, it is necessary to provide training sessions, workshops, and ongoing support, to demonstrate the value of new data analytics tools.

Integration Challenges

The importance of data integration cannot be overstated. However, integrating new analytics tools with existing (and sometimes legacy) systems and workflows can be complex and time-consuming.

How to address it: Using APIs and middleware solutions is the option to make integration seamless. First, it would be necessary to conduct thorough compatibility assessments to ensure everything works together smoothly.

Data Security and Privacy Concerns

Construction firms typically deal with sensitive data, and there’s often concern about how securely that data is being stored and used.

How to address it: Implementing encryption, access controls, and regular security audits, as well as outline your security protocols clearly to build trust with clients and stakeholders are the best practices to ensure data security and address privacy concerns.

Complexity of Data Interpretation

With so much data in construction being generated, it’s easy to feel overwhelmed. Sifting through the “bad” data to find useful information can be a significant challenge.

How to address it: To simplify data interpretation, it is necessary to use intuitive dashboards and data visualization tools. Customizing reporting options for the particular project to focus on the most relevant metrics is also a way to reduce the complexity of data interpretation.

Inadequate Data Infrastructure

Some construction firms don’t have the infrastructure to handle advanced data analytics, making it difficult to fully leverage new technologies.

How to address it: Experts recommend using cloud-based solutions to start small and expand as your data needs grow — without heavy upfront investments in physical infrastructure. It would also be wise to reap the advantages of strategic technology consulting to get professional tips on infrastructure enhancements.

Changing Stakeholder Requirements

In construction, stakeholder requirements can evolve throughout the project lifecycle, sometimes leading to scope creep or misalignment with the project’s original goals.

How to address it: Using Agile project management methodologies to easily adapt to changes in stakeholder requirements and regularly gather feedback to ensure alignment with evolving needs is the best practice to manage changing requirements effectively.

Make Use of Construction Data Insights with Professional Tech Support

To implement data analytics in construction and bypass the obstacles we just mentioned, seeking professional support is the smartest move you can make. Here’s why:

- Access to specific expertise in machine learning development, AI, IoT, and beyond.

- Faster time-to-value with no learning curve involved.

- Effective integrations with existing systems, ensuring zero disruption.

Partner with a Reliable Data Analytics Development Vendor

At SPD Technology, we’ve got relevant experience in the construction industry, along with profound AI and ML expertise. Here’s why we’re a perfect match for your construction project:

Extensive Experience with Construction Data Analytics Technologies

We’ve worked on multiple data analytics projects for the construction industry.

In particular, we delivered an AI/ML-powered platform that predicts, detects, and manages defects in equipment. It integrates multiple machine learning algorithms, including NLP, object recognition, and anomaly detection, to analyze video, image, and sensor data effectively. It also lets users create digital twins and generate maintenance insights.

Our other significant data analytics solution successfully tackles another task — predictive maintenance. It features a real-time data monitoring system, data visualization, and automated failure detection, among other things.

Our background also includes building a data analytics system for a construction company capable of managing and analyzing over 70 million records. This system uses an OLAP Data Lake system, serverless technology, and customizable dashboards to deliver efficient performance.

Prioritizing Stakeholder Engagement

Construction projects involve various stakeholders, from contractors and subcontractors to architects, engineers, and clients. We do everything to foster straightforward communication among all parties. That’s why we offer intuitive dashboards and reporting tools that keep everyone in the loop.

Comprehensive Training and Support

Beyond just implementing construction data analytics tools, we make sure your team can use them properly. Our experts support your staff in leveraging these tools effectively, providing hands-on training sessions, and easy-to-follow resources. We offer ongoing support as well.

SPD Technology’s Case Study — HaulHub Construction Data Analytics System Development

Our client, HaulHub, is a B2B2C transportation construction company that provides data collection and automation technologies for government and industrial sectors. They merged four advanced solutions into one multifunctional platform for heavy construction businesses and were seeking support in expanding their mission-critical software.

Business Challenge

To expand the platform’s capabilities, we had to tackle several challenges. First of all, we had to deal with complex business logic and an immense amount of ticketing data (over 70 million records!). Besides that, we were supposed to create an OLAP system, develop and train AI models, and provide robust data analysis capabilities — all while ensuring the platform’s scalability.

SPD Technology’s Approach

We developed mobile and web applications to meet HaulHub’s needs for a comprehensive transportation construction solution. We also enhanced the code quality and integrated data from internal systems and third-party sources to ensure smooth data flow, visualization, and reporting.

For the AI-powered part, we implemented models for various tasks. This included generating responses to user queries, summarizing documents, comparing content, drafting reports, processing images, and using search and recommendation systems.

Value Delivered

We leveraged our software and data engineering expertise to enable such platform capabilities as digital inspection, live construction activity view, activation and deactivation of digital work zones, worker presence analysis, automated traveler alerts, environmental product declarations reporting, as-built tracking, and more.

Conclusion

Data analytics is changing the entire construction industry for the better. It improves project planning, reduces costs, promotes sustainability, and offers enhanced safety and risk management — the essentials for smarter decisions and thriving projects.

As construction data analytics tools get more advanced, combining VR, AR, artificial intelligence and the Internet-of-Things, their applications in the construction industry will only expand.

If you’re aiming to make sense of your construction data and implement powerful analytics tools, SPD Technology can help. Our data analytics services are backed up by years of experience, a deep understanding of the construction industry, and numerous satisfied clients. Get in touch with us to learn how our data analytics solutions can transform your business.

FAQ

How are big data and analytics transforming the construction industry?

Big data and analytics are transforming the construction industry by:

- Improving project planning and scheduling.

- Providing more accurate project cost estimation and budgeting.

- Enabling careful environmental impact assessment.

- Enhancing safety and risk management.

- Improving client and stakeholder transparency.

How is data analytics used in the construction industry?

There are various applications of data analytics in construction. The main ones include:

- Quality control and defect detection.

- Predictive maintenance of equipment.

- Labor and productivity management.

- Supply chain and resource management.

- Safety monitoring and risk mitigation.